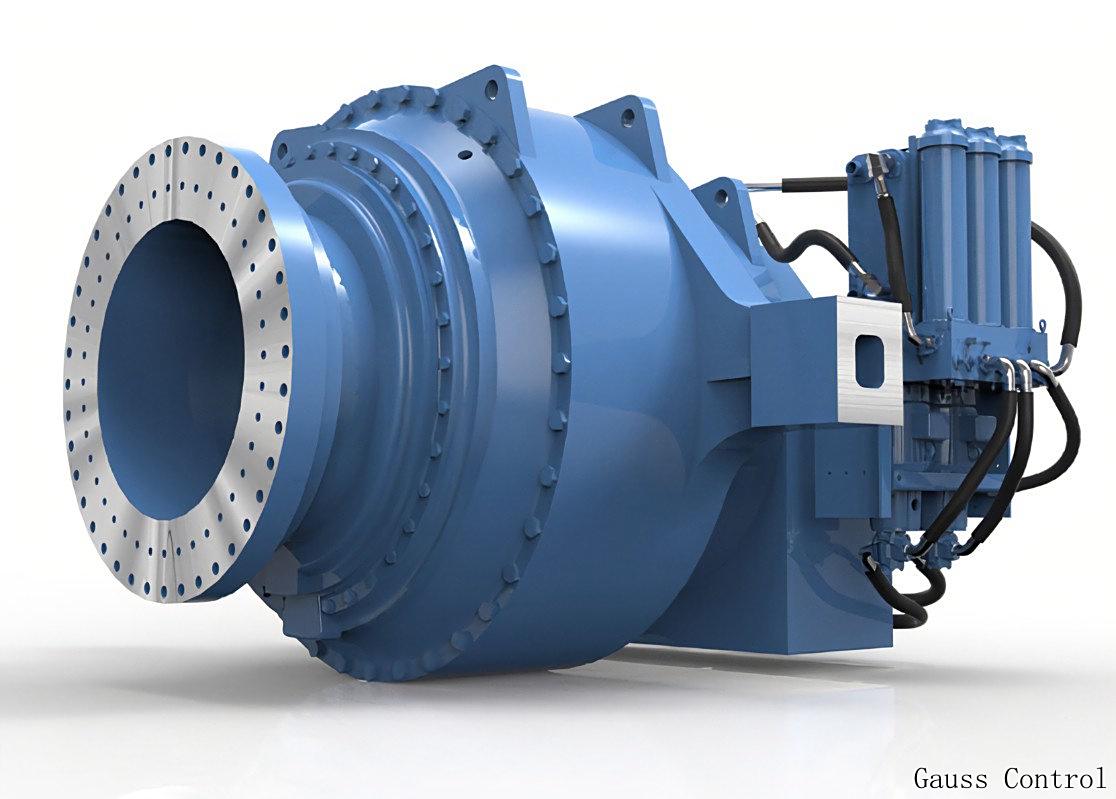

Wind Energy gearboxes are subjected to high dynamic loads and require long-term reliability. Their design must exhibit fatigue strength, precision characteristics, and weight optimization. The gears within these gearboxes undergo heat treatment to enhance resistance against bending fatigue loads and surface contact fatigue. This process increases surface residual compressive stress, improving fatigue life while maintaining a ductile core.

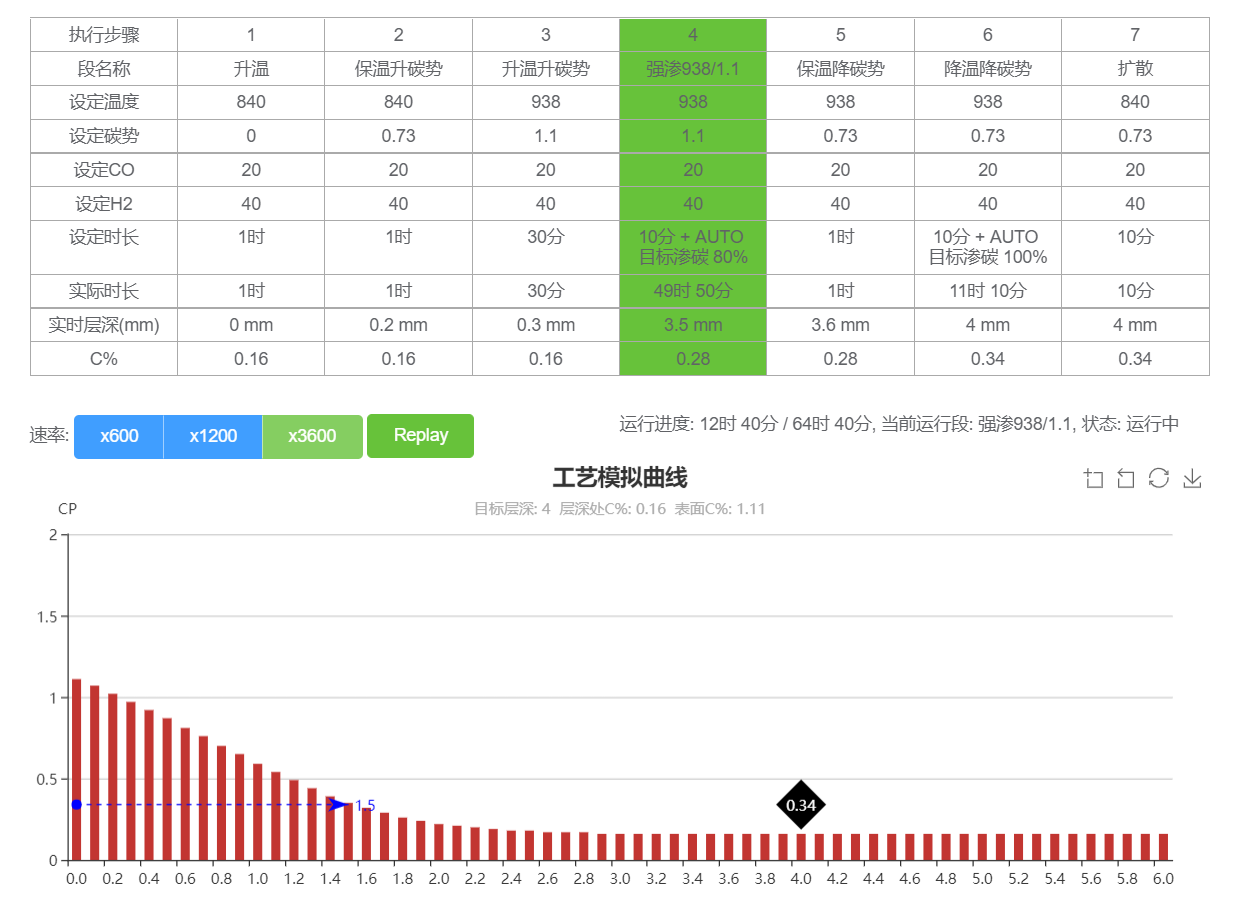

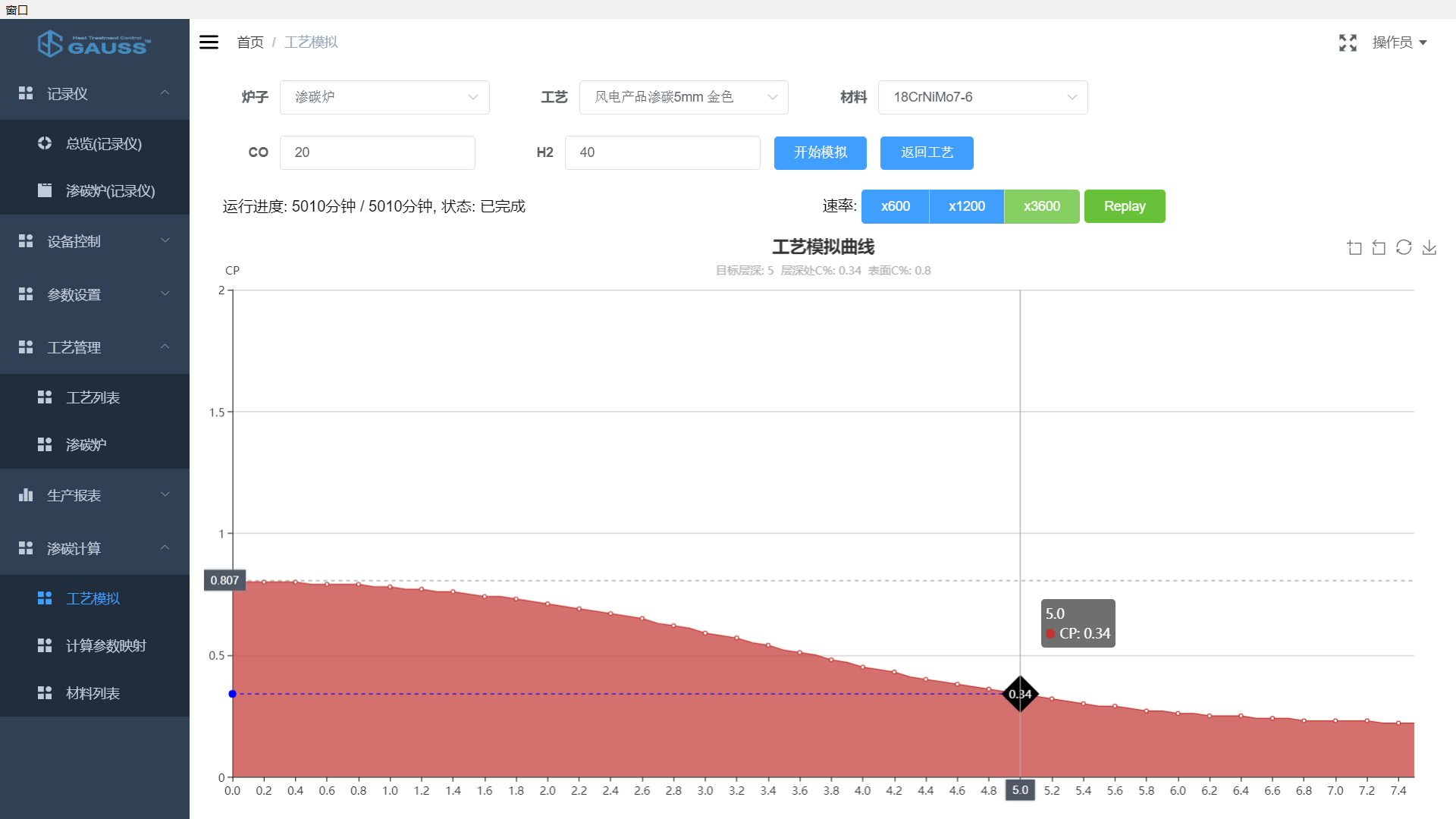

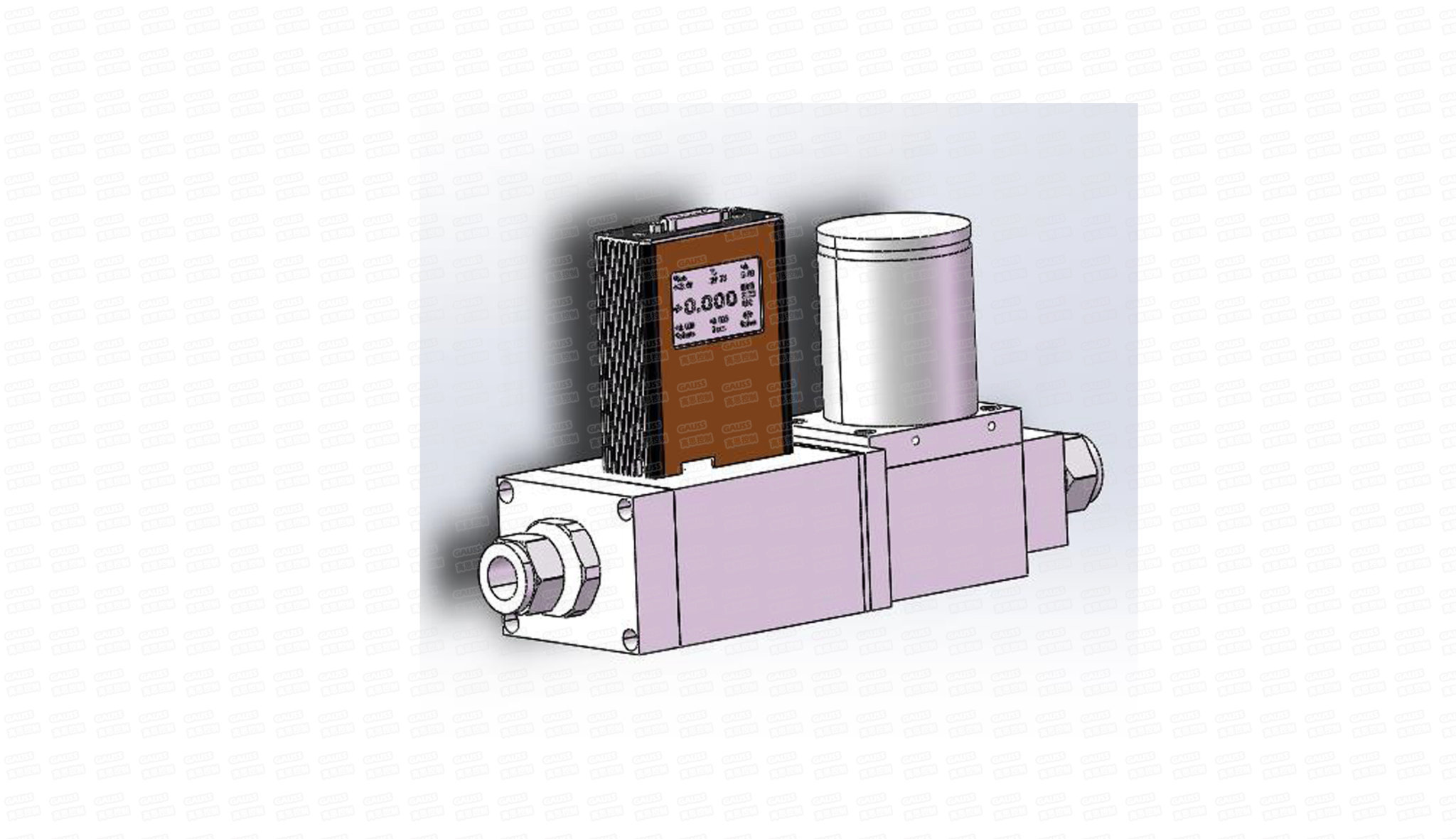

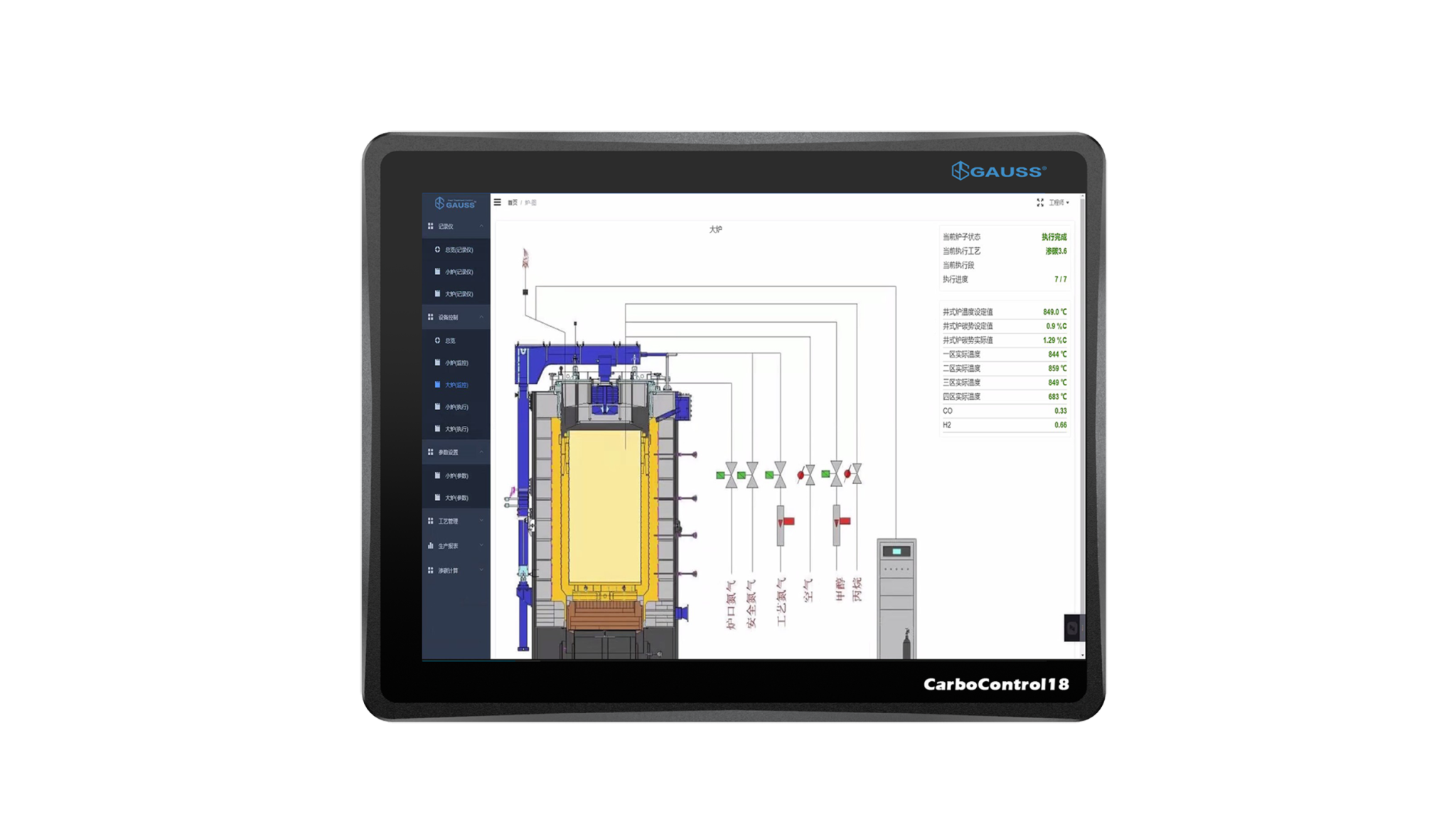

To achieve these goals, precise and reliable heat treatment process control systems are crucial. With years of experience, Gauss has developed cost-effective nitriding process control systems and core components that offer a viable alternative to foreign brands.