The automotive industry faces a multitude of challenges, ranging from consumer-driven price and reliability expectations to increasingly stringent environmental and efficiency requirements. Gauss continuously refines its existing product performance and innovates to meet new customer demands, serving this rapidly evolving industry.

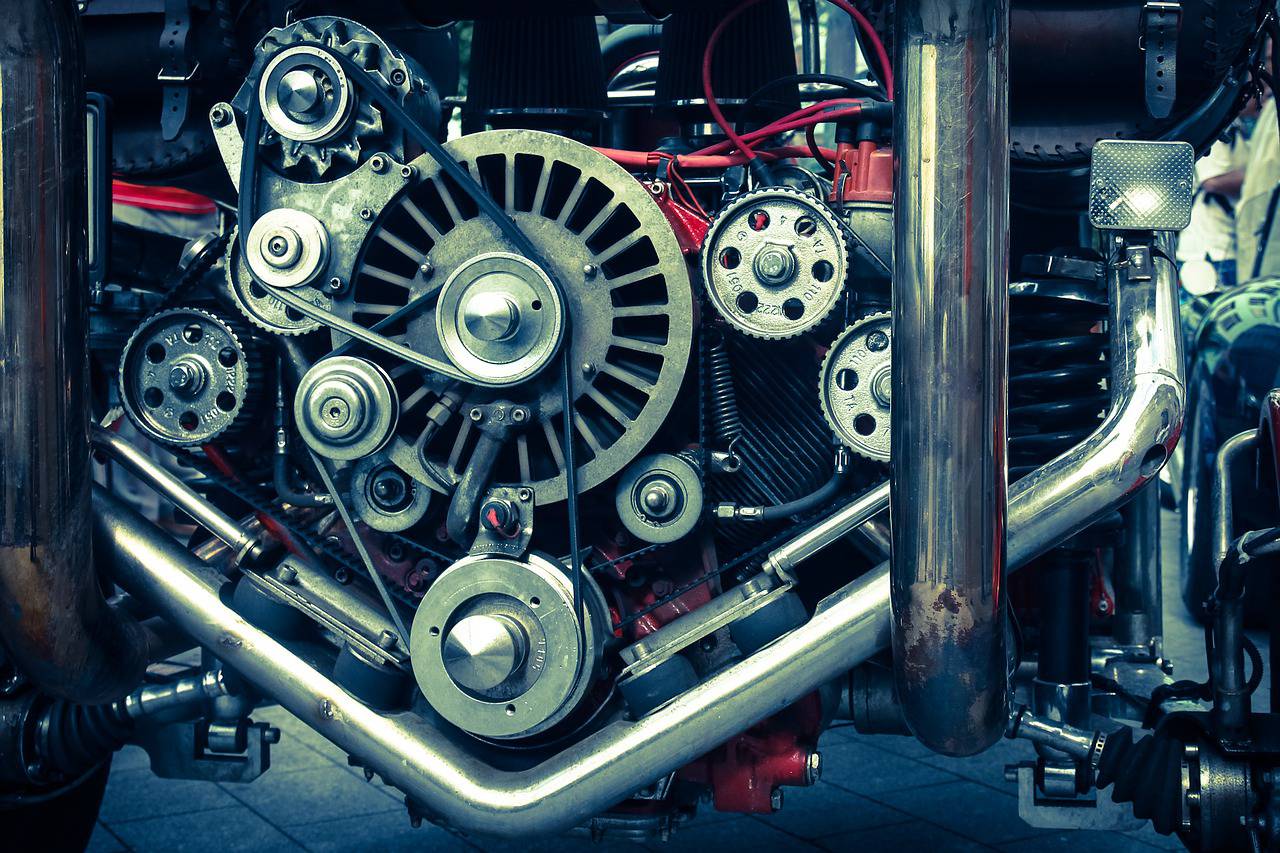

Engine and transmission systems involve a variety of critical, high-speed rotating components that operate in high-temperature corrosive environments. Toughness, surface wear resistance, and excellent fatigue strength are essential qualities. To guarantee quality, a high level of execution within the quality management system is crucial.