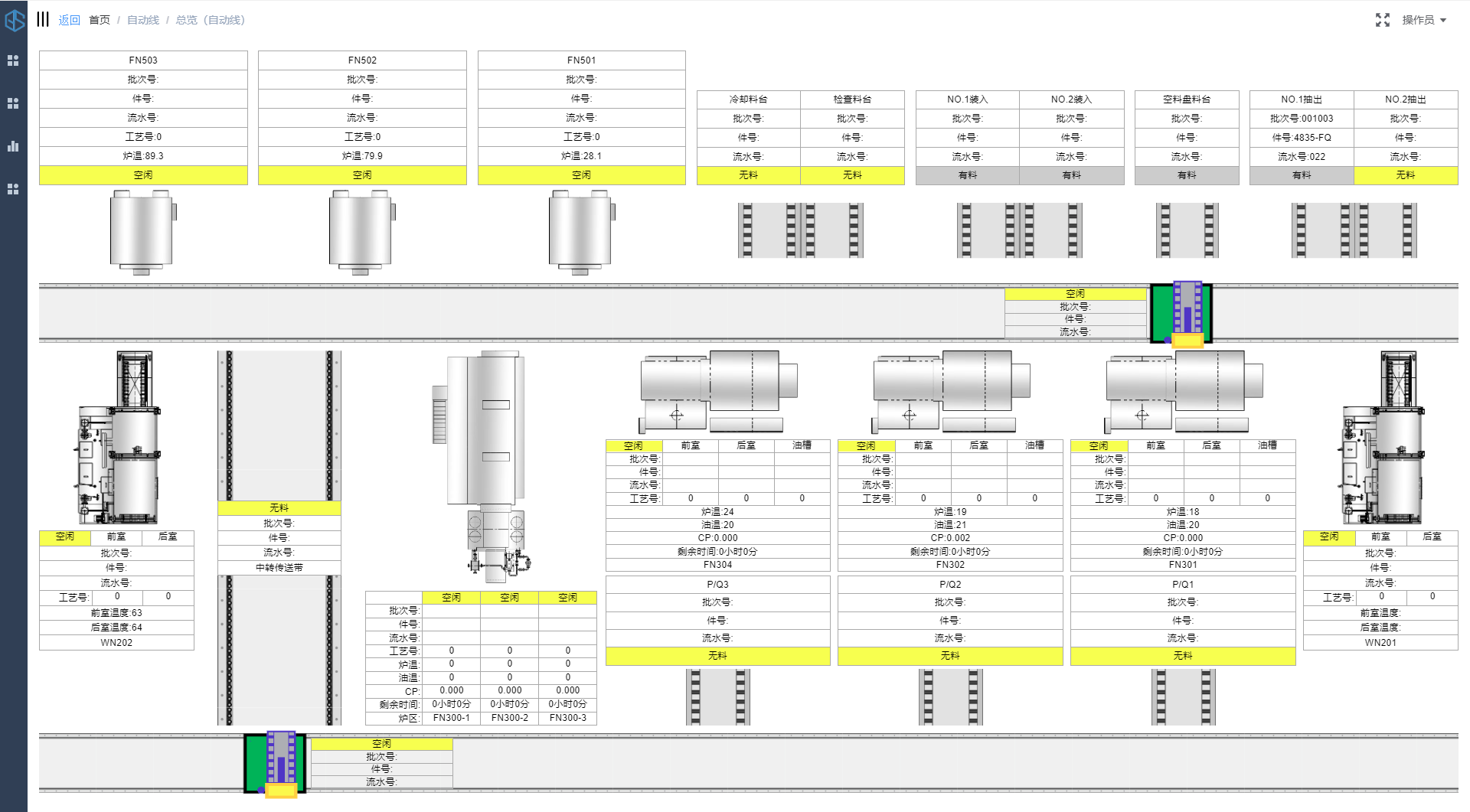

GS2025 Automatic Production Line

Fully automated production lines enable completely unmanned production, minimizing human intervention in equipment operation. This not only enhances efficiency but also reduces quality issues during the heat treatment process and plays a positive role in extending the service life of the equipment.

In a fully automated heat treatment production line, the worker only needs to scan the batch of workpieces about to enter the line. After scanning, the process flow and information of the workpieces are entered into the system. Then, the worker uses a lifting device to load the workpieces onto the production line. The system server has already arranged the production procedures and time, and the workpieces undergo heat treatment according to the established plan. Once the treatment is complete, the system places the batch of workpieces on a preparation table, waiting to be unloaded. The worker then uses the lifting device again to unload the workpieces, completing the entire heat treatment process.